Fermentation Technology

Fermentation: An art from the past, a skill for the future…

Brain McNeil

What is fermentation?

Ø Fermentation is a metabolic process which converts carbohydrates to alcohols, organic acids or gases by the activity of enzymes of microbial origin.

Ø Microbes involved in fermentation process: Bacteria and Fungi.

Ø The process of anaerobic respiration in the muscle cells of animals during exercise which produce lactic acid is also a type of fermentation.

Ø The technique of fermentation was very ancient in origin.

Ø Egyptians and Sumerians had the knowledge of the technique of converting starchy grains to alcoholics.

| You may also like NOTES in... | ||

|---|---|---|

| BOTANY | BIOCHEMISTRY | MOL. BIOLOGY |

| ZOOLOGY | MICROBIOLOGY | BIOSTATISTICS |

| ECOLOGY | IMMUNOLOGY | BIOTECHNOLOGY |

| GENETICS | EMBRYOLOGY | PHYSIOLOGY |

| EVOLUTION | BIOPHYSICS | BIOINFORMATICS |

Ø For a microbiologist, the word ‘fermentation’ means many processes such as:

$ A method of mass cultivation of microbes under aerobic or anaerobic conditions.

$ Any biological process occurs in the absence of oxygen.

$ Spoilage of food by microbial activity.

$ Production of alcoholic beverages, organic acids, antibiotics or biopolymers

$ Partial oxidation of carbohydrates

What is industrial fermentation?

Ø The intentional use of fermentation technology for the large scale production of microbial biomass or metabolites is called industrial fermentation.

Ø Fermented products have immense use in food, medicine and other industries.

Ø Modern industrial fermentation units use genetically engineered microbes for the rapid production of desired metabolites.

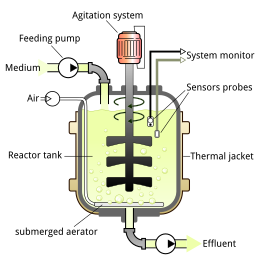

What is a fermenter?

Ø The heart of industrial fermentation is a ‘Fermenter’.

Ø Fermenter is type of bioreactor*

Ø Fermenter: a system provided with controlled environmental conditions for the growth of microbes in liquid culture and production of specific metabolites.

Ø It is a device in which the microbes are cultivated and motivated to form the desired products.

Ø It is containment system to provide the accurate environment for the optimum growth and metabolic activity of the microbes.

Ø Fermenter prevents the entry and growth of contaminating microbes from outside.

Ø Fermenter: containment system for the cultivation of prokaryotic cells (bacteria) and fungi

Ø Bioreactor: containment system for the cultivation of mammalian or insect cells

Ø A fermenter possesses the following mechanical parts:

$. A large vessel made of stainless or rust free material.

$. Motors provided with an automatic control system.

$. Heaters with thermostat system for providing and manipulating temperature.

$. Pups for the addition or removal of substances and water to the fermenter.

$. Gas source and pipeline system for aeration.

$. Sensors for pH and aeration.

$. Peripheral manual or automatic controlling facilities.

Ø The mechanical components of the fermenter proves:

$. A space for taking raw material (culture media / carbon source)

$. Provide a contamination free environment for the growth of microbes.

$. Maintain optimum temperature in the system.

$. Provide adequate mixing and agitation in the medium.

$. Provide ample aeration for aerobic fermentation.

$. Control and maintain optimum pH condition in the fermenter

$. Monitor the concentration of dissolved oxygen in the system

$. Allow the addition of nutrients in between the fermentation process (in continuous fermentation)

$. Facility for maintaining a wide range of organisms.

$. Provision for collecting over-flow from the fermenter (in continuous fermentation)

What are the different types of fermentation process / methods?

Ø There are three types of industrial fermentation processes based on the methods of fermentation and types of fermenters.

(1). Batch fermentation

(2). Continuous fermentation

(3). Fed-batch fermentation

(1). Batch Fermentation

Ø Microorganism is inoculated into a fixed volume of medium.

Ø As the growth takes place, the nutrients are consumed and the product of growth accumulates in the fermenter.

Ø Product of growth may be of two types: (a) Biomass and (b). Metabolites.

Ø The nutrient environment in the fermenter is continuously changed.

Ø This change in the environment in the fermenter will enforce change in the metabolism of cells.

Ø This also results in the cessation of cell multiplication.

Ø Cessation of growth is due to the scarcity of nutrients and accumulation of metabolites.

Ø Once the microbes reached the stationary phase they start to accumulate the metabolites.

Ø Metabolites are extracted from the fermenter by downstream processes.

Ø After the fermentation is over, the residues are taken out from the fermentation tank, and the vessel is then cleaned and sterilized before next batch of fermentation.

Ø Thus in batch fermentation, the large scale production is done as separates ‘batches’.

Ø Microbes in the batch culture show the following pattern of growth with distinct phases.

(1). Log phase: initial phase, no apparent growth of microbes, they adapt to the environmental conditions.

(1). Log phase: initial phase, no apparent growth of microbes, they adapt to the environmental conditions.

(2). Transient acceleration: the inoculum begins to grow slowly.

(3). Exponential phase: microbial growth proceeds at the maximum possible rate.

(4). Deceleration phase: decline in the growth rate of microbes

(5). Stationary phase: no overall growth rate (death of the cells equals to the division of cells). Most of the secondary metabolites are produced in this phase.

(6). Death phase: no growth at all, cells starts to die and the population size decreases. Usually the fermentation stops before the death phase.

(2). Continuous Fermentation

Ø Here the exponential growth rate of the microbes is maintained in the fermenter for prolonged periods of time in by the addition of fresh media are regular intervals.

Ø Microbes reach the exponential growth rate and continue as such due to the availability of nutrients.

Ø The exponential growth rate of microbes continues till the vessel becomes completely filled in the cells.

Ø Continuous fermenter possesses devices for the collection of overflow from the vessel.

Ø The metabolite or the product of fermentation is extracted for the overflow by downstream processing.

Ø Thus unlike batch fermentation, in continuous fermentation, the fermentation process never stops in between and it continues to run for a long period of time with the addition of nutrients and harvesting the metabolites at regular intervals.

Learn more: Difference between Batch Fermentation and Continuous Fermentation

3. Fed-batch fermentation

Ø It is a modified version of batch fermentation.

Ø Here the substrate is added in increments at different times throughout the course of fermentation.

Ø Periodical addition of substrate keeps the prolonged log and stationary phase of the microbes in the fermenter.

Ø This results in the rapid increase of biomass.

Ø Consequently increased production of metabolites can be achieved in the stationary phase.

Ø Thus fed-batch technique is an improved version of fermentation by avoiding the disadvantages of batch and continuous fermentation techniques.

<< Back to Biotechnology Notes

| You may also like... | ||

|---|---|---|

| NOTES | QUESTION BANK | COMPETITIVE EXAMS. |

| PPTs | UNIVERSITY EXAMS | DIFFERENCE BETWEEN.. |

| MCQs | PLUS ONE BIOLOGY | NEWS & JOBS |

| MOCK TESTS | PLUS TWO BIOLOGY | PRACTICAL |

Super easily observed

Thank you for that